Anping Tori Wire Mesh Co.,Ltd.

Wire Mesh Product And Service

MOB: +86-15833839680

FAX: +86-18732807300

ADD: Wire Mesh Industrial Zone, Anping Hebei China

Email:

TEL:+86-318-8097300

MOB:+86-15833839680

FAX:+86-18732807300

EMAIL:

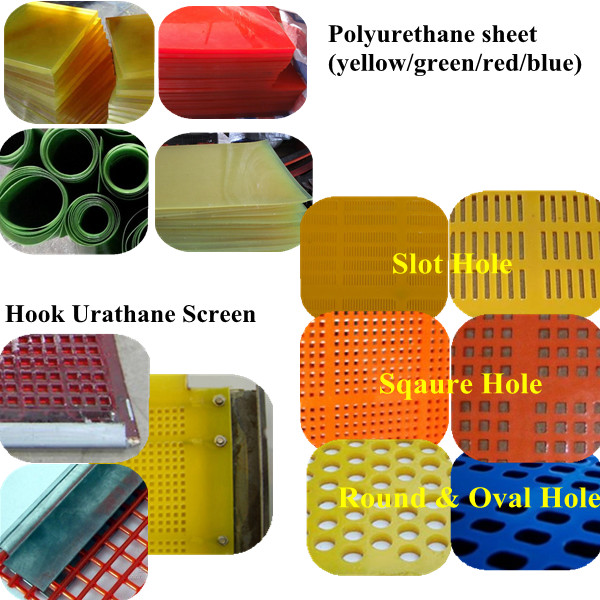

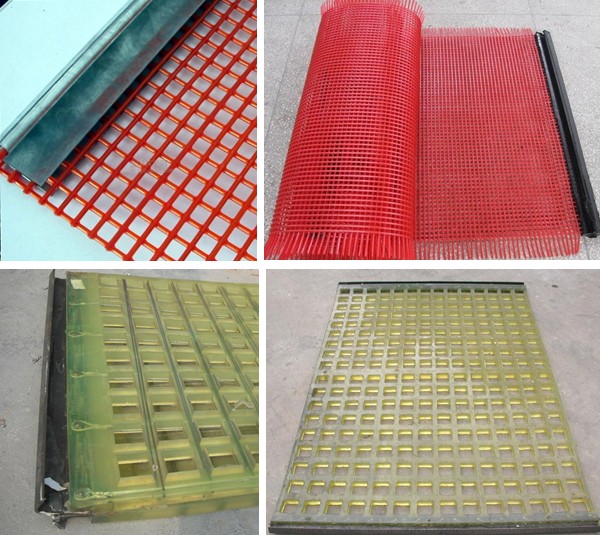

Mine Screen included crimped mesh screen panel, perforated mesh screen panel, welded mesh screen panel and polyurethane screen panel.

The polyurethane Screen panel is a new product for mine

The Polyurethane Screen is more efficiency, long working time, anti-abrasive and lower noise.

Now is widly used in mine industry as well as used for coal/rock/sand rinsing and dewatering area.

Advantages:

1) Superior capacity and performance with high open area of 35 to 45 percent

2) Reduced operating and maitenance costs from long life and ease installation

3) Available with opening as fine as 75 microns( 200 mesh)

4) Practically non-blinding

5) Can be repaired or patched in place

6) Custom mold design

7) Suited to variaty of wet and dry applications

8) Low working noise

9) Economical, though the price is alittle higher than the metal screen,it is performance is more better than the metal screen,and to displace the metal screen is a curtain thing in future

Applications

- Hard rock mining

- Quarrying

- Coal processing

- Fine sizing

- Dewatering

- Drain and rinse screening

High Ribbed Form work is manufactured from hot-dipped galvanized steel sheets. Because its meshes and U patterns, it has better anti-stress capability and forming flexibility than normal metal lath. This product has excellent engineering quality, construction security and widely used in tunnels bridges, valve basement systems, sewage systems, subways, retaining walls, nuclear power plants, shipyards, water pools and marine engineering works and high rise building projects and non-regular or bending pattern etc.

High Ribbed Form work is manufactured from hot-dipped galvanized steel sheets. Because its meshes and U patterns, it has better anti-stress capability and forming flexibility than normal metal lath. This product has excellent engineering quality, construction security and widely used in tunnels bridges, valve basement systems, sewage systems, subways, retaining walls, nuclear power plants, shipyards, water pools and marine engineering works and high rise building projects and non-regular or bending pattern etc. Perforated mild steel is sheet that has been punched with a series of holes to give you a nominated pattern. The pattern can vary depending on the hole size, distance between holes and the thickness of the material. Perforated mild steel has many various uses including catering for the architectural, chemical, mining & refining, the uses are endless.

Perforated mild steel is sheet that has been punched with a series of holes to give you a nominated pattern. The pattern can vary depending on the hole size, distance between holes and the thickness of the material. Perforated mild steel has many various uses including catering for the architectural, chemical, mining & refining, the uses are endless.ADDR: Wire Mesh Industrial Zone, Anping Hebei China ZIP:053600